Learn methods to capture, control, dispose, and derive the condensation requirements within HVAC systems.

Learning Objectives:

- Evaluate the code requirements for condensate pipe sizing and how to adapt these for additional use.

- Analyze psychrometrics and how this impacts condensation on building interiors and exteriors.

- Illustrate dew point and how supply air temperatures impact condensation within buildings.

- Explain the code requirements of cooling coil installations above ceilings.

Condensation is one of the simplest and most recognizable displays of psychrometrics in our daily lives. Most people can remember in their childhood seeing the “sweating” of a soda can or on the outside of an ice-cold glass of water on a summer day. At that time, we didn’t understand the physical factors behind this display. Mostly, we just tried to keep the glass from dripping on ourselves or on our mother’s table.

Basics of psychrometricsFrom a mechanical engineering practice in commercial buildings, condensation and condensate are found as part of the air and water systems. This article focuses on the air- and water-side components as they relate to the air conditioning. We typically refer to condensation as it forms on building elements (diffusers, windows, mirrors, etc.) and condensate as it forms on HVAC cooling coils (fan coil units, air handling units, etc.). These two are closest in relation and are due to the same psychrometric points used to provide conditioned air to a space.

Condensate is water that is drawn out of the air stream as it passes through the cooling coil to reach the required leaving-air temperature for space conditioning. It forms as air is cooled beyond its dew point where the dry bulb (DB) temperature equals the wet bulb (WB) temperature (see Figure 1). This figure indicates the standard psychrometric state points for air conditioning within Macau, China. This area possesses a high WB temperature and relative humidity year-round and especially during the summer months. These conditions result in a significantly higher condensate flow rate and formation of condensation on building elements present in other areas, such as Las Vegas.

The quantity of water condensed out of the airstream is equal to the difference in water mass flow rate between the two state points. In the case of Figure 1, condensate forms as the air is sensibly cooled from the mixed-air temperature (MAT) state point of (83.4°F DB/73.9°F WB) down to the respective dew point of 70.1°F. At this point, the air cannot be cooled further with the same quantity of moisture present (under standard HVAC conditions). The humidity ratio and absolute humidity must decrease to maintain the air state point within the bounds of the psychrometric chart. As the air moves down the saturation line to the leaving air temperature (LAT) 51.8°F DB/51.3°F WB) a mass flow rate of water is condensed out of the air.

The quantity of water formed into condensate is determined from the following physical properties of the airstream:

- Mass of moisture in the air as part of the humidity ratio at each point between the mixed-air temperature and leaving-air temperature (kilogram/kilogram or pounds/pound of moisture per unit of dry air): ΔW

- Specific volume of the air (cubic meter/kilogram or cubic foot/lbm): V

- Airflow rate of supply air being cooled from the mixed-air condition to the leaving-air condition off the cooling coil (liters/second or cfm): Q

The equation will produce a flow rate in mass per unit of time by default (seconds or minutes based upon the airflow rate). This is due to the specific volume factor, but it can be easily converted to a water flow rate in l/s or gallons per minute by converting from mass to volume of water (1l = 1 kg and 1 gal = 8.34 lbm). Along with these volumetric flow rates, we can derive the code requirements and better explain the correlation between refrigeration tons (kilowatts) and condensate pipe sizing, which will be discussed in greater depth later in this article.

Code requirements

Below are excerpts taken from the 2015 International Mechanical Code (IMC), which directly relate to equipment requirements, pipe sizing, routing, and termination.

307.2 Evaporators and cooling coils: Condensate drain systems shall be provided for equipment and appliances containing evaporators or cooling coils. Condensate drain systems shall be designed, constructed, and installed in accordance with Sections 307.2.1 through 307.2.5.

Exception: Evaporators and cooling coils that are designed to operate in sensible cooling only and not support condensation shall not be required to meet the requirements of this section.

307.2.1 Condensate disposal: Condensate from all cooling coils and evaporators shall be conveyed from the drain pan outlet to an approved place of disposal. Such piping shall maintain a minimum horizontal slope in the direction of discharge of not less than 1/8-unit vertical in 12-units horizontal (1% slope). Condensate shall not discharge into a street, alley, or other areas so as to cause a nuisance.

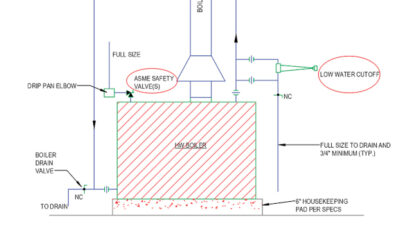

307.2.2 Drainpipe materials and sizes: Components of the condensate disposal system shall be cast iron, galvanized steel, copper, cross-linked polyethylene, polyethylene, ABS, CPVC, PVC (polyvinyl chloride), or polypropylene pipe or tubing. Components shall be selected for the pressure and temperature rating of the installation. Joints and connections shall be made in accordance with the applicable provisions of Chapter 7 of the International Plumbing Code relative to the material type. Condensate waste and drain line size shall be not less than 3/4-in. internal diameter and shall not decrease in size from the drain pan connection to the place of condensate disposal. Where the drainpipes from more than one unit are manifolded together for condensate drainage, the pipe or tubing shall be sized in accordance with Table 307.2.2. Please review Table 307.2.2 for specific refrigeration tonnage and condensate piping sizes.

The condensate drain piping must be provided with a U-type trap prior to being indirectly drained into the approved receptor (floor sink, planter, etc.). The trap height is as required to compensate for the negative fan pressure in draw-through units and allow for draining of condensate without backing up into the drain pan itself. This liquid trap prevents air from entering or leaving the equipment casing while allowing for condensate to drain away from the unit.

Condensate pumping for HVAC equipment

An accepted design method that is not directly noted within the code is the usage of condensate pumps to move condensate up from a low level or reduce the piping slope impact within a ceiling space. These pumps are used in both floor- and ceiling-mounted installations where the discharge level of the condensate pipe is not able to gravity-drain to the adjacent condensate main lines or indirect drain receptor.

These pumps are commonly electrically powered, include a reservoir of 1 gal or less, and fitted with a check valve at the pump discharge to prevent condensate from flowing back into the pump reservoir after the pump shuts off. The pumped condensate piping typically matches the gravity piping and connects to the top of the main line at its connection point to prevent gravity condensate from flowing back into the pumped line and better direct its flow path.

Condensate pumps are low-flow and higher head units for their size and are selected for open-system requirements (the pump head is selected to overcome the friction losses in the piping as well as the static height of water necessary to reach the discharge point).

Two important items to review when determining which pump can be applied to a specific design are noise of the pump operation and pump construction.

- As the condensate pumps operate intermittently to remove liquid from the associated reservoir, the noise they produce during operation is more pronounced to occupants. Intermittent noise is typically more noticeable to people rather than continuous noise (provided they are at equal and relatively low levels). The continuous noise will fade into the background over a period of time, while intermittent noise will be noticed each time the level changes during the same period. This issue typically prevents condensate pump usage within private offices, guest rooms, spa treatment rooms, or other areas where an occupant will be present for longer periods and will notice changes in background noise level.

- Pump construction is of greatest concern for pump installations in noncombustible-construction building return-air plenums (International Building Code, IBC, Type 1A, for example). For large buildings with return-air plenums, plenum-rated or noncombustible (metallic) construction is typically necessary to comply with the building code requirements. This limits the specific types of condensate pumps to serve equipment installed in the plenum, as some brands and types are only provided with ABS or similar tank construction. This type of construction does not meet the flame-spread and smoke-developed index requirements as noted within ASTM E84 and referenced within the IMC/IBC.

Calculations of the IMC requirements

The condensate drainpipe sizing indicated in table 307.2.2 provides code compliance and a conservative analysis with combining systems onto main lines. This table is extremely useful and fills the requirements for most system types, but in large buildings, main condensate risers or pipes can exceed the tonnages listed and require extrapolation to determine the associated pipe size. Using the formula identified in the previous psychrometric example for the flow rate of condensate per unit of supply air, we can determine the anticipated allowable cooling load that can be accommodated by piping larger than 2 in.

Using the psychrometric state points from Figure 1, the anticipated condensate flow rate is 0.012 gpm/ton. When combined with the gravity-flow limitations of horizontal piping sloped at the code-required 1%, this results in approximately 42 tons of load for a ¾-in. pipe size. This is too large a load for the given pipe size, as the code values should not be exceeded, but it helps to illustrate the minimal flow that is achieved from a cooling coil even at 50% outside air in a humid climate. Even at 100% outside air with the Macau design condition, the gallon per minute per ton is similar. The reason for this is as the differences in humidity ratio increase, the quantity of supply air for 1 ton (12,000 Btu or 3.5 kW) of refrigeration decreases. The common 400 cfm/ton decreases down close to 100 cfm/ton at full outside-air load (due to the high latent load and enthalpy present in the outside airstream).

Using the code-required tons of refrigeration per pipe size as a control, we can infer that the gallon per minute per ton is closer to 0.025. With this value, along with specified friction factors and velocities of condensate in the horizontal piping system, we can extrapolate the table shown in Table 1. In addition to the refrigeration capacity per pipe size, an equivalent chilled-water flow rate has been included using a 14°F water-temperature differential. This has been useful on past hotel tower projects where the condensate piping follows the chilled-water risers to serve guest-room fan coil risers, which allows the designer to size both the chilled water and condensate piping simultaneously with a single equivalent flow rate (though small fan coils typically can only achieve approximately a 12°F water-temperature differential).

Cooling coils installed above ceilings

In the 2015 IMC, section 307.2.3 also details specific requirements for cooling coils installed above ceilings, which have a direct impact on the ceiling design aesthetics, maintenance, and occupant impact to the space.

307.2.3 Auxiliary and secondary drain systems: In addition to the requirements of Section 307.2.1, where damage to any building components could occur as a result of overflow from the equipment primary condensate-removal system, one of the following auxiliary protection methods shall be provided for each cooling coil or fuel-fired appliance that produces condensate:

1. An auxiliary drain pan with a separate drain shall be provided under the coils on which condensation will occur. The auxiliary pan drain shall discharge to a conspicuous point of disposal to alert occupants in the event of a stoppage of the primary drain. The pan shall have a minimum depth of 1.5 in., shall not be less than 3 in. larger than the unit or the coil dimensions in width and length, and shall be constructed of corrosion-resistant material. Galvanized-sheet steel pans shall have a minimum thickness of not less than 0.0236 in. (No. 24 gage). Nonmetallic pans shall have a minimum thickness of not less than 0.0625 in.

2. A separate overflow drain line shall be connected to the drain pan provided with the equipment. The overflow drain shall discharge to a conspicuous point of disposal to alert occupants in the event of a stoppage of the primary drain. The overflow drain line shall connect to the drain pan at a higher level than the primary drain connection.

3. An auxiliary drain pan without a separate drain line shall be provided under the coils on which condensate will occur. The pan shall be equipped with a water-level detection device conforming to UL 508 that will shut off the equipment served prior to overflow of the pan. The auxiliary drain pan shall be constructed in accordance with Item 1 of this section.

4. A water-level detection device conforming to UL 508 shall be provided that will shut off the equipment served in the event that the primary drain is blocked. The device shall be installed in the primary drain line, the overflow drain line, or in the equipment-supplied drain pan, located at a point higher than the primary drain line connection and below the overflow rim of the pan.

Exception: Fuel-fired appliances that automatically shut down operation in the event of a stoppage in the condensate drainage system.

307.2.3.1 Water-level monitoring devices: On downflow units and all other coils that do not have a secondary drain or provisions to install a secondary or auxiliary drain pan, a water-level monitoring device shall be installed inside the primary drain pan. This device shall shut off the equipment served in the event that the primary drain becomes restricted. Devices installed in the drain line shall not be permitted.

Auxiliary and secondary drain best practices

Cooling coils installed above ceilings can pose various design challenges to comply with IMC section 307.2.3. Among the options available to engineers/designers, the most commonly implemented are options 1, 2, and 4.

Options 1 and 2 provide a visual indication of a blockage in the primary drain connection and require no power or interfacing requirements for shutdown of the associated equipment. In addition, most equipment manufacturers provide secondary overflow drain connections as standard within enclosed horizontal fan coil units to meet the requirements of option 2.

The standard piping installation for this compliance provides an open-ended condensate drainpipe terminated just below the ceiling construction with an escutcheon plate to finish the penetration and mitigate condensate reaching the ceiling construction. These options allow for the continual operation of the associated equipment, even if the primary drain is blocked, which is beneficial in areas where maintaining conditioning is more important than dripping condensate onto the floor for a period of time before maintenance identifies and corrects the problem. This includes systems such as fan coils serving electrical or telecom rooms installed above ceilings outside the rooms. This installation is typically suited for back-of-house spaces or areas that are not interior design-driven. The termination point is occasionally brought down a wall to terminate below a lavatory sink counter to further conceal its appearance, but the overflow termination location must be visible for maintenance review and correction.

Option 4 is more acceptable and used in front-of-house spaces, or where the discharge of an overflow condensate drain may cause disruption to the occupied space. This option is useful in areas, such as tower guest rooms, where finding an appropriate location to terminate the overflow condensate without impacting the interior design, the guest experience, or their property can be challenging.

This option relies on several design methods, such as a float switch or level sensor in the drain pan or an overflow cutoff switch mounted in the condensate drainpipe. Once the cutoff switch or level float senses impending overflow, it shuts down the associated conditioning equipment. An alarm may be sent at this time, but in areas such as tower guest rooms, the equipment may not be connected to the building-management system and would only alarm locally or through an in-room control system. This option may result in guest complaint due to the equipment shutdown, but it assists in quickly identifying issues with the installation.

Condensation in air-side systems

Beyond the general requirements of condensate management from HVAC cooling coils, condensation on building elements can cause issues in humid climates or within high-humidity spaces, such as indoor pools and spas. For these areas, the same psychrometric process governs the formation of condensate; but unlike on a cooling coil, once condensation forms there is no proper or direct path for it to drain. This results in hazards and damage from water dripping off of metal-diffuser surfaces onto the ground below or ceiling adjacent (causing walking hazards, mold growth, or damage to the ceiling construction).

In humid climates, such as Florida and Macau, the simple act of washing the windows with conditioned air (as is common in Las Vegas to cool the envelope load at the source) results in water condensing on the outside of the windows and the appearance of fog or rain during the normal day. The 55°F supply air exiting the typical diffuser is well below the dew point of the outside air, which in Macau is 79.6°F. Even with insulated glass, exterior condensation can form on windows in Macau during the mornings.

The space dew point and supply air temperatures play heavily into indoor pool designs, especially in spa spaces where the water temperature is typically maintained at 104°F and the air is maintained at 84.2°F and 55% relative humidity. As mentioned above and shown on the psychrometric chart in Figure 2, for the mechanical system to operate properly within this space, the supply air must exit the diffuser at a DB temperature above the dew point of the space. In addition, the WB temperature of the supply air must be sufficiently depressed (lower than the DB) so that the air can dehumidify the space. Both the latent loads produced by the people and by water evaporation from the pool/spa surface must be accounted within the sensible heat ratio (SHR) calculation as standard for determining the supply air DB and WB temperatures. This equation can be generally described as the following:

This equation should include all forms of heat generation throughout the cooling cycle and from each side of the coil to account for the total cooling load, with the space loads taken within the typical floor-to-ceiling volume. The maximum value for SHR is 1.0, as this would mean that no latent load is present and all loads are downstream of the cooling coil (placing the fan motor heat within the theoretical space boundary, which will sensibly heat the air after leaving the cooling coil). For office space, the SHR may be as high as 0.9—but for an indoor pool or spa, this value may be down closer to 0.5 due to the high latent loads present in the space.

This highlights the complexities of high-humidity spaces within buildings. The misapplication of a standard office HVAC design inside of an indoor pool space will cause considerable condensation issues, drafts, occupant discomfort, physical hazards, and construction compromises with mold growth and damage to the building surfaces. Proper calculations and understanding of psychrometrics are necessary to deliver the best system for each application.

Matt Dolan is a senior mechanical engineer with JBA Consulting Engineers. His expertise is in designing complex HVAC and plumbing systems for various building types, such as commercial offices, health care facilities, and hospitality complexes including numerous high-rise guest-room towers and restaurants.