Automatic transfer switch short-circuit current protection has some common misconceptions. Here we’ll discuss the deficiencies of “non-current limiting” protection.

Automatic transfer switches (ATSs) are a vital part of many life safety and mission critical systems where continuity of service is crucial. The NEC requires 600 V or less ATSs to be “listed for emergency system use” when installed in these systems. UL 1008, Transfer Switch Equipment, is the product standard for ATSs.

When designing a power system and specifying an ATS, two important design considerations must be evaluated: An ATS’s withstand and closing (close on) rating (WCR), and how the overcurrent protective device (OCPD) protecting the ATS affects system selective coordination. A misapplication of the relationship between an ATS and its OCPD can have a severe impact on the integrity of the system and on the overall project cost. This article focuses on ATS short-circuit current protection and the common misconceptions and deficiencies of “non-current limiting” protection.

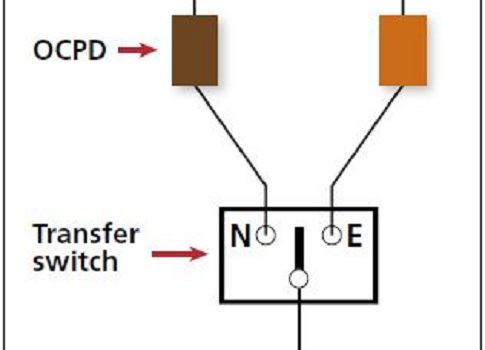

A clear understanding of the relationship between an ATS’s WCR and the OCPD is imperative to assure a well-designed installation (see Figure 1). An ATS must be properly protected for short-circuit currents from either source of power, or in the case of closed transition ATSs, the combination of the fault current from each source. If an ATS is subjected to a fault current above its maximum WCR, severe damage (including a potential fire hazard and arc flash hazard), severe injury, or death may result.

Options for ATS protection

ATSs generally are tested, listed, and labeled for use with either fuses or circuit breakers, each offering different levels of protection. Within this standard there are two main short-circuit current withstand tests an ATS must surpass. First, the ATS must withstand a short circuit when the switch is in a closed position. During the second withstand test, the ATS must transfer, close, and hold on to the short circuit. ATSs must pass both of these tests at the same available short-circuit current magnitude and survive within a specified acceptable damage criterion.

Figures 2 and 3 are aids for understanding the protection options and illustrate a typical ATS manufacturer’s data available for proper specification and application. Figure 2 is a sample label for a 400 A ATS. The label is typically affixed on the inside door of the enclosure. The label would be useful during installation, inspection, and post-installation alterations. Figure 3 is a WCR table for all the ampere ratings for a manufacturer’s specific ATS series. This would be useful during the specification/procurement process. The Figure 2 label and Figure 3 table are fictitious and for illustrative purposes only. When interpreting actual manufacturer’s WCR tables and equipment labels, be sure to read all pertinent footnotes, referenced materials, etc.

Circuit breaker protection options

ATSs protected by circuit breakers can be classified by one of three WCRs:

- “Specific breaker” rating

- “Any breaker” rating: 3-cycle circuit breaker rating

- Short time rating (18 to 30 cycles): circuit breakers without instantaneous trip.

These three ATS short-circuit protection options for circuit breakers are indicated in Figures 2 and 3 by the corresponding number (1), (2), or (3).

(1) “Specific breaker” WCR

For an ATS switch to receive a “specific breaker” rating in accordance with UL 1008, it must be short-circuit current tested when protected by a specific circuit breaker (manufacturer, type designation, and ampere rating). ATS manufacturers typically provide documentation for specific circuit breaker choices that have been tested and listed for a particular ATS. See Figure 2, option 1, for a sample label. Figure 3, Specific Breaker Rating column marked (1), provides the levels of protection, in amperes, achievable through the use of specific breakers for a particular ATS series. To view the list of specific breakers tested and accepted, contact the ATS manufacturer.

Certain issues may arise when specific breaker combinations are used. It is important to note that specific breaker ratings are usually a hindrance on bid day because, in most circumstances, the vendors providing the circuit breaker and the ATS are not the same. This places extra responsibility on the contractor and consulting engineer to make sure the ATS/circuit breaker pair is a tested, listed combination. Specific breaker combinations are often highly scrutinized by the authority having jurisdiction (AHJ) during an inspection. Although a specific breaker may be properly short-circuit combination rated with the ATS at the time of the initial installation, it is very likely that over the life of a system, the circuit breaker may need to be replaced. The person tasked with finding a replacement circuit breaker may not fully understand the importance of the relationship between the circuit breaker and the ATS it is protecting. If a new circuit breaker is installed that differs in type and/or rating, it may not be listed to protect the transfer switch and could be a potential hazard. Finally, if proper maintenance is not performed, the trip characteristics of circuit breakers may change as they age. The tripping time may become slower, thus exposing the ATS to energy above its tested and marked WCR rating.

(2) “Any breaker” WCR

The 3-cycle rating was introduced into UL 1008 in 1989. It allowed ATS manufacturers to provide another rating category for short-circuit current WCR. An ATS that passes this test is able to withstand a fault of a given magnitude for 3-cycles* and not exceed certain damage criteria (See Figure 2, option 2; and Figure 3, column marked (2)).

The purpose of the test is to allow an ATS to be marked for use with any manufacturer’s circuit breaker that incorporates an instantaneous trip when the ATS and circuit breaker are applied within their ratings. The umbrella ratings provided by this test give an engineer more flexibility when specifying circuit breaker protection for an ATS. In the past this option was thought to alleviate many of the procurement, installation, or replacement issues that occur when using the “specific breaker” option above. For this reason, the rating was referred to as the “any breaker” rating and was considered the best practice solution when using circuit breakers for ATS protection. This, however, has changed with the advancement and growing understanding of selective coordination.

* Per UL 1008, for 400 A or less ATSs tested for 10 kA any breaker WCR, the time withstand is only 1.5 cycles.

(3) Short time WCR with circuit breakers

New considerations for ATSs came to the forefront with the addition of selective coordination requirements for emergency systems, legally required standby systems, and healthcare essential electrical systems to the 2005 NEC.

Designers desiring selective coordination with circuit breakers often use circuit breakers with short time delay and no instantaneous trip in vital systems. These circuit breakers increase the time that an ATS must withstand a short-circuit current. Because the short-time delay opening time will likely exceed the 3-cycle time limit for the 3-cycle “any breaker,” option 2 of Figure 2 and column 2 of Figure 3 cannot be used.

Because of selective coordination requirements circuits powering life safety-related loads, the 3-cycle “any breaker” ratings that were previously the norm for ATS protection in circuit breaker designs are no longer sufficient in many cases. Practical example: If the circuit breaker protecting the ATS has an intentional short time delay of 0.1 seconds (6 cycles), a 3-cycle “any breaker” rating will not provide adequate protection for the ATS.

In recent years, ATS manufacturers have introduced short time rated ATSs to aid in circuit breaker designs requiring selective coordination. The short time test subjects an ATS to a given fault current for up to 30 cycles. The options available for ATSs with short time ratings are limited and also usually carry a higher price tag when compared to ATSs with standard WCRs. (See Figure 2, option 3; and Figure 3, column (3)).

Fuse protection option for ATS WCR

The other option for ATS protection is the use of current-limiting fuses. The current-limiting ability of fuses limits let-through current and thereby reduces the damaging energy during a fault. This assures the ATS will be protected even when exposed to very high fault levels, in most cases up to 200 kA. The combination tested fuse class and maximum amp rating is given by ATS manufacturers along with the WCR protection level (See Figure 2, option 4; and Figure 3, column (4)). In addition to the ease in achieving ATS WCR of 200 kA because of their current-limiting ability, fuses are easy to achieve selective coordination, even for high fault currents.

Another important consideration is the availability of ATS options for the different protection options just discussed. When protected by fuses, typically ATSs with any option can be used and the ATS will have a 200 kA WCR. However, when protected by circuit breakers, the designer or installer must be vigilant to verify the ATS WCR for various configurations or ATS options based on the type of circuit breaker used. The following lists outline some of the ATS characteristics that must be evaluated to adequately specify fuse or circuit breaker protection for ATS WCR.

What determines an ATS’s WCR when protected by fuses

- Only the switch amp rating and the fuse UL class/max. amp rating. (Almost all ATSs, regardless of manufacturer, amp size, and options used, have a WCR of 200,000 A when protected by current-limiting fuses.)

What determines an ATS’s WCR when protected by a circuit breaker

- ATS manufacturer (ASCO, Russelectric, Zenith, Cummins, Caterpillar, Eaton, Kohler, etc.)

- ATS Series (i.e., 300,4000,7000)

- Voltage (240,480,600)

- Frame size (amp rating)

- Bypass/Non-bypass switch

- Number of poles (2,3,4)

- Type of neutral (solid, switched, overlapping)

- Connection type (front/rear connect, mechanical/compression lugs)

As you can see in the second list, many factors define the protection level provided by a circuit breaker. Following the ATS manufacturer’s WCR chart (similar to Figure 3), a specifier or installer cannot be assured that in all applications a circuit breaker will provide adequate protection. Common configurations will actually afford an ATS with a lower WCR in certain cases. For one major manufacturer, an ATS from 260 to 600 A has a 42 kA, 3-cycle WCR at 480 V when protected by an instantaneous trip circuit breaker. However, with a 4-pole overlapping neutral this ATS would only have a rating of 35 kA when protected by an instantaneous circuit breaker. These same ATSs protected by appropriate fuses have a 200 kA WCR.

Another commonly overlooked design concern is the connection type chosen for the ATS. Certain ATSs have optional front, rear, or side connect versions to help accommodate sizing concerns and aid in installation. For instance, an ATS when designed as a rear connect switch is rated for 65 kA WCR with instantaneous trip circuit breaker protection, but it may have only a 50 kA WCR if the front connect version is chosen. Similarly, when protected by a circuit breaker, the WCR for an ATS may vary with the type of cable connections specified. While in most cases the standard connection type for ATS installation is mechanical screw-type lugs, many projects request compression lugs for ATSs. This will, in most cases, also adversely affect the WCR given to an ATS when protected by a circuit breaker. If using fuse protection, these ATS characteristics are a non-issue and the WCR is typically 200 kA.

Proper emergency system design requires full understanding of the relationship between a transfer switch and the systems overcurrent protection. Many factors—such as available fault current, overcurrent device coordination, and even the accessories chosen for a given ATS—could have dramatic impact on protection requirements. By failing to investigate all available options or failing to consider variables during the construction process and over the life of a system, a serious misapplication may occur. Likewise, diminished protection ratings or significant and unnecessary costs and size implications for the ATS may be introduced to a design. With insufficient design scrutiny, these issues may exist during the initial construction process or could surface during the future life of the system.

Hospital ATS example

There are severe cost implications due to the proper selection of an OCPD for an ATS. Let’s look at a common ATS example. The following pricing example has been taken from a real ATS quote and is a common occurrence across ATS manufacturers. The manufacturer’s name and part numbers have been omitted.

Requirement:

A consulting engineer needs to specify the following for a hospital patient wing addition. In the design, circuit breakers will be used upstream to protect the ATSs. Quantity: Five automatic transfer bypass isolation switches, 600 A, 480 V, 4-pole switched neutral, with a NEMA 1 enclosure.

Initial ATS cost estimate

From ATS manufacturer:

The estimated cost per switch: $15,000

Cost for 5: $75,000

Footprint dimensions per switch: 34 in. x 28 in. (height not considered)

ATS cost modified due to fault current

However, when the available fault current is calculated, it is determined that there is a 58 kA root means squared (RMS) symmetrical short-circuit current available at the ATS. The designer concludes that these ATSs will require a 65 kA 3-cycle WCR. (This assumes instantaneous trip circuit breakers will be used without short time delay.)

After reviewing the WCR chart provided by the ATS manufacturer (similar to Figure 3), the engineer discovers the ATS quoted above is only rated to withstand 42 kA for 3 cycles. In order to assure the ATS can withstand a fault current of this magnitude, it is necessary to move up to the next ATS frame size, and purchase an ATS with adequate WCR. The next frame size offered by this ATS manufacturer is 800 to 1200 A. The engineer again reviews the WCR chart and learns that a switch of this size is only rated for 50 kA for 3 cycles. Again, this will require the move up to an even larger ATS. The next ATS frame size manufactured is 1600 to 2000 A. After reviewing the WCR chart, the consultant sees that these switches can withstand faults of 85 to 100 kA depending on the required ATS characteristics. Either way, this switch will be able to withstand the 58 kA available and meet the 65 kA 3-cycle requirement. The consultant goes back to the ATS manufacturer for a new price.

From ATS manufacturer:

The new cost per switch: $35,000

Cost for 5: $175,000

Footprint dimensions per switch: 38 in. x 60 in.

Additional cost

$20,000 per ATS x 5 = $100,000 to owner

Additional electrical room floor space required = 20 in. x 160 in.

This is a very common situation. It may or may not be made clear during a bid or submittal review that these changes have occurred, but the added costs are real. These additional costs are in most cases figured in by the ATS manufacturer during the initial bid and never questioned. When using circuit breakers, a substantial price premium can be incurred when the system has higher available short-circuit currents. The larger ATSs will also take up more floor space in already crowded electrical rooms.

An alternative solution would be to use fuse protection. If current limiting fuses are specified upstream of the ATS, the energy let through during a fault will be far below the withstand threshold of the ATS, allowing the original 600 A ($15,000) ATS to be protected from any fault up to 200 kA. With fuse protection, the original ATS cost estimate would be applicable. This, in turn, would have saved the end user over $100,000, reduced overall project completion time, and conserved floor space.

Right-size to avoid change orders

The following is another real ATS example. This illustrates issues that may arise after initial design.

A consulting engineer specifies an ATS protected by circuit breakers. The engineer calculates the available fault current as designed at the ATS to be 48 kA and labels the drawings accordingly. After reviewing the drawings, the contractor purchases an ATS with a WCR of 50 kA.

When installing the conduit and pulling the cables, the contractor finds a shorter path to run the cabling to the ATS than originally planned and is able to save on conductor material and installation costs. The ATS is manufactured, shipped, and installed at the job site. When the “as installed” short circuit and coordination study is conducted, it is determined that the available fault current at the ATS is now 52 kA. The ATS, however, is only rated to withstand a fault of 50 kA. An inspector will not approve this ATS that is not rated for use with the maximum available fault current, plus there is a liability if installed in this manner. If the contractor requests a return and purchases a properly rated ATS from the manufacturer, there will be severe change order cost involved.

This situation is common across the industry. An alternative solution would have been to use fuse protection, which is typically 200 kA WCR, and eliminate the need to “right-size” the system every time a project plan change is made.

Stanek is a field applications engineer for Cooper Bussmann and has spent the entirety of his career specializing in emergency system design both with Bussmann and working as a field applications engineer for a major ATS manufacturer. Through his experience working in the field with consulting engineers, contractors, and system owners, he has encountered countless misapplications of transfer switch protection.