Incorporating set thermal comfort criteria provides many benefits while increasing the use of high-performance HVAC systems for energy reduction.

Learning Objectives:

- Analyze thermal comfort criteria for improved user experience.

- Consider partial-cooling systems.

- Maximize value through zone cooling and heating.

Thermal comfort is an indoor environmental-quality feature that has proven to impact productivity. Variables that impact the air temperature at which one may feel comfortable are clothing, metabolic activity, indoor air temperature, humidity, radiant temperature, and air speed. In addition to these factors, user expectation can also shift if the space is naturally conditioned using operable windows with the availability of control. The variability of thermal experience may be different when naturally cooled using operable windows, which may be considered in conjunction with biophilia as an enhancing addition.

Thermal comfort standards

The 2013 edition of ASHRAE 55: Thermal Environmental Conditions for Human Occupancy specifies methods to determine indoor thermal environmental conditions that a significant number of occupants would find acceptable. The standard details thermal comfort for mechanically and naturally ventilated spaces, based on the following factors:

- Clothing

- Metabolic activity

- Indoor air temperature

- Humidity

- Radiant temperature

- Air speed.

The U.S. Green Building Council (USGBC) LEED and International Well Building Institute WELL Building standard refer to ASHRAE 55 for compliance. The WELL Building standard includes thermal comfort as a precondition for certification, with radiant thermal comfort and individual thermal comfort as optimizations for high levels of certification. The USGBC LEED guideline, in addition to ASHRAE 55, provides an option to use International Organization for Standardization (ISO) and European Committee for Standardization (CEN) standards. LEED includes one credit for meeting the thermal comfort requirements per ASHRAE 55 and providing individual controls for 50% of the individual occupant spaces.

Operative temperature is simply defined as the average between air temperature and the mean radiant temperature. This is because the temperature experienced or perceived by the user is based on the heat exchange with the immediate environment, through convective and radiant heat loss, or heat gain to our surroundings. The air temperature impacts the convective heat exchange and the mean radiant temperature of the surfaces around us impacts the radiant portion of the heat exchange. Operative temperature is how one may experience indoor temperature, even though a space is typically controlled or monitored solely using air temperature. This is often one of the main contributors to occupant thermal discomfort, even when the air temperature meets the typical 75°F during cooling conditions. ASHRAE 55 also establishes the acceptable operative temperature range for naturally conditioned spaces.

Heating and cooling design criteria

HVAC systems are generally designed for a predefined heating and cooling setpoint (typically between 70° and 75°F for heating and cooling simultaneously), based on 99.6% dry-bulb temperature for winter design conditions and 0.4% or 1% dry-bulb temperature for summer design conditions. In addition to this, there are numerous assumptions that have to be made for the cooling loads regarding infiltration, envelope, lighting, occupancy, and plug loads. Fifteen-percent oversizing for cooling and 25% oversizing for heating is also typically allowed, however these allowances are slowly being eliminated by codes.

For the end user, this does not provide much clarity on what to anticipate in terms of hours above the comfort threshold, especially with changing outdoor temperatures due to global warming. The design conditions also are typically based on air temperature, even though the radiant temperature, along with other factors previously mentioned, can change the perception of comfort to a large extent. Typically, a thermostat in a space is controlled by air temperature, yet what is experienced or sensed is operative temperature. Ongoing discussions should consider the following questions:

- Should the industry define new mechanical-design criteria instead of continuing to use the ASHRAE setpoints as the design conditions?

- Should there be conversations with clients to establish appropriate and acceptable thermal comfort criteria set for their building?

- How often do buildings in reality use a lower cooling set point than 75°F, perhaps due to a perception of higher temperature in the space?

The goal of the criteria would be to create designs that can allow for variability and prevent oversizing to meet unforeseen conditions or extreme peak conditions. Oversized systems do not achieve thermal comfort for 100% of users and can lead to over-cooling of spaces for a portion of occupants, especially during shoulder seasons. Establishing set thermal comfort criteria will allow for enhanced mechanical design for varying outside conditions of spaces with operable windows, rather than focus alone on a fixed setpoint at peak design conditions. Operable windows can provide free economizer cooling, while the mechanical system provides the minimum ventilation required during conditions when windows may not be opened due to outside temperatures, noise, or odors.

The reason to discuss adaptable thermal comfort criteria is not only to limit overdesign, but also to provide solutions that can make it possible to integrate the use of operable windows with HVAC systems. An enhanced indoor/outdoor connection is often discussed during design, but due to air conditioning, it is often limited to large amounts of glazing with views to outside in place of a true connection. Other hurdles for operable windows include acoustics, air quality, and allergens. New true connections between the indoors and outdoors may be associated with health and wellness characteristics.

Currently, these don’t carry additional credit within the WELL Building or the LEED guidelines, but they are included as a separate pathway to thermal comfort. These goals and objectives can provide truly integrated design opportunities between architects and mechanical engineers to maximize the value of the building envelope. The potential to allow natural conditioning when appropriate can impact the depth of spaces, further enhancing occupant daylight and views. The envelope is where the architectural and mechanical conversations need to start, which should include operable windows, glazing percentage and specification, and external shading to allow for more efficient mechanical systems.

In addition to maximizing user comfort and experience, using adaptive thermal comfort design criteria can potentially:

- Decrease initial costs by reducing the need to overdesign

- Reduce annual energy and utility costs

- Increase the potential to use high-performance HVAC systems to meet energy-reduction goals and reduce global warming

- Open up the possibility for systems that can meet net zero potential for some buildings.

Making a case for partial-cooling systems

The meaning of partial cooling can vary based on the intent, but simply stated, the design is not projected to meet the required 75°F setpoint during peak outdoor conditions based on 0.4% or 1% dry-bulb temperature for summer design conditions. Partial cooling is designed to meet set thermal comfort criteria, which allow a set number of hours above 75°, 80°, or even 85°F. The hours are determined using ASHRAE 55 or by discussions with the owner, often based on what might lead to complaints or what they are contractually required to provide.

There are several reasons to understand and embrace the concept of partial cooling as an alternative to full cooling.

- Partial cooling can enhance the use of operable windows when outside air conditions are optimal, expanding the indoor-air band that is deemed comfortable.

- Partial cooling can help quantify and optimize the building form; fine-tuning the envelope is key to integrating partial cooling.

- Partial cooling can allow the building to "sail" through the shoulder months, but still provide some thermal stability by means of a right-sized mechanical ventilation and cooling system during peak conditions.

- Using natural cooling can potentially allow ductwork to be sized for 100% outside air, which can provide the benefit of improved indoor air quality year-round, due to eliminating the mixing of return air.

- In some cases, buildings are able to incorporate a geothermal heat pump system, because it is sized for heating conditions and provides partial cooling only. If this system was to be sized for full cooling, it would have to be oversized and would be beyond the project budget or even the required site area. Sizing for the peak cooling load can change the system type selected for the building due to budget or space needs.

- When developing set thermal comfort criteria, partial cooling can be discussed to optimize the system type for thermal comfort throughout the year, annual energy and utility cost savings, and potentially better usability and control of operable windows.

Designing for annual climate conditions

The outside air conditions designed for are usual peak conditions. System choices, options, and recommendations would be different with a deeper understanding of the climate, and even more so if the goal is to set thermal comfort criteria. A better understanding of operating hours and temperature bins for a variety of ranges would provide different insight. Annual, hourly weather data is available through a number of different sources.

Spaces should be designed for thermal comfort criteria instead of a setpoint. For some locations, with the right architectural design, this would provide a way to eliminate cooling systems altogether and reduce infrastructure due to reduced number of hours when cooling is absolutely required.

Use of energy and thermal modeling can help engineers make envelope recommendations, such as shading and glazing specifications, as well as limit the size of the systems and/or incorporate more efficient systems like radiant ceilings, which are harder to model and size using conventional sizing tools. Advanced tools can help quantify the number of hours spaces may be above required temperature setpoints or if they meet the set thermal comfort criteria.

Mechanical engineers should play a larger role in helping architects define the envelope so the control of thermal comfort can be optimized. This includes glazing percentage, interior shades, etc. that are typically not discussed with mechanical engineers.

This approach could increase the viability of a larger number of deep green buildings, due to the decrease of the financial impact of oversizing systems that only serve a handful of hours in a year.

Adaptive thermal comfort is often discussed during the initial design phases. However, implementing adaptive thermal comfort requires a risk factor, and clients often shy away so as to minimize occupant complaints.

Adaptive thermal comfort

In the Pacific Northwest, these conversations require an understanding of the regional climate. Not having cooling is slowly becoming a rarity, despite the potential to achieve passive cooling through design. The following ideas need to be addressed by the industry or through conversations with the client or users of the spaces:

- Is the connection to the outdoors being lost by the use of cooling instead of designing operable windows for use during desirable weather?

- Are there benefits in changing the way access to the outdoors is designed to allow for some variability in the space conditions, rather than a monotonous constant temperature and environment?

- How could providing controls to open the louvers to the outside when the weather meets desired conditions be integrated into the design?

- How many hours in a year during which indoor air temperatures are above 75° or 78°F are acceptable to the client? Are ceiling fans acceptable?

An adaptive thermal comfort strategy requires integration and in-depth conversations between engineers and architects in determining the glazing percentage in the building based on orientation, shading, operable window free area, and glazing solar-heat gain values. The integrated design team needs to evaluate the envelope to optimize for daylighting as well as to reduce cooling loads by means of dedicated performance analysis. Additionally, thermal comfort modeling can highlight features that can be detrimental to thermal comfort in a space, like large glazing areas or glazing specifications that can lead to high mean radiant temperatures.

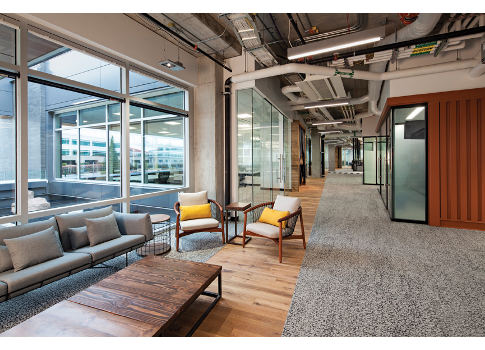

Maximizing value through zone cooling and heating

Zone heating and cooling systems provide myriad benefits. Most importantly, these systems can provide improved thermal comfort due to the localized zone-level access to cooling and heating. These zones are typically served by a dedicated outside air unit to meet the outside air requirements as well as any latent loads in the space. This allows for improved indoor air quality due to 100% outside air and no return air from zones (which may include off-gassing from interior materials). These system types can also allow higher ceiling heights due to reduced ductwork, leading to improved daylight and/or user experience. Savings from these systems go beyond the utility costs to include enhanced user experience as well as potential cost savings due to reduced floor-to-floor height. These system types are being included in local energy codes and will be mandatory by 2017 per the 2015 Washington State Energy Code.

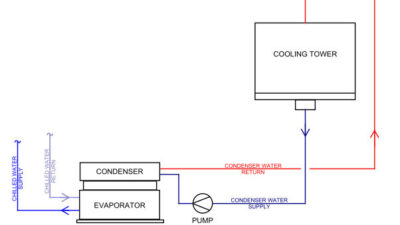

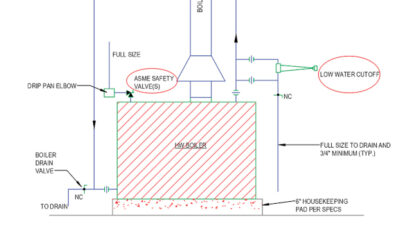

Options for zone cooling and heating systems can vary from fan coil units, water-source heat pumps, and variable refrigerant flow systems to active chilled beams, passive chilled beams, chilled sails, or radiant ceilings. Thermal comfort, energy, and utility cost savings also vary based on the zone system type and the central plant configuration. The majority of savings are a result of decreased fan-energy use due to reduced air handling unit fan size. The cooling energy can increase as a result of reduced free economizer hours during shoulder season, but this is often overcome by more efficient central plant equipment or higher chilled-water temperatures, or water side heat recovery.

Radiant cooling systems and chilled-beam systems

The zone system selection is highly dependent on the predicted peak cooling load within the space. Maximum energy savings and thermal comfort benefits may be extracted from a radiant-ceiling-type system. However, this system is the least popular due to its limited cooling capacity. For this system type, a complete consensus is necessary from both the architect and the owner to minimize cooling loads.

The building envelope needs attention to ensure solar loads are minimized by means of optimum glazing percentage, glazing specifications, and external shading. Partial-cooling criteria can allow for a more flexible design, maximize energy, and utility cost savings. Radiant cooling can keep a space comfortable at higher air temperatures; however, this is often hard to quantify and is not considered due to limitations and associated risk of how thermal comfort is controlled and used by peak mechanical sizing tools.

Other factors that limit the use of radiant-cooling-type systems is higher internal loads as a result of plug loads. These are sometimes harder to anticipate, thus they are eliminated as an option in spaces where plug loads are very high. Examples for systems with partial-cooling criteria include the Bullitt Center in Seattle, which is the nation’s largest Living Building Challenge office building (energy use intensity (EUI) is 16 kBtu/sq ft/year), and the National Renewable Energy Laboratory’s office building in Golden, Colo., which is the nation’s largest net zero office building (EUI is 35 kBtu/sq ft/year). Another example, which did not use the partial-cooling option but includes radiant cooling, is the Edith Green-Wendell Wyatt Federal Building modernization project in Portland, Ore. (EUI is 32 kBtu/sq ft/year).

A chilled-beam system is a zone heating and cooling system that is becoming a popular design option as firms are becoming more experienced with its design and performance. This system uses a dedicated outside air system and provides zone cooling and heating, but due to the additional air induction it has a higher cooling-capacity allowance. This system may require more than minimum outside air, due to its impact on the cooling capacity of the chilled beam.

The active chilled-beam system without partial-cooling potential was selected for a high-tech office building in Kirkland, Wash. Numerous options were studied for this project, but an active chilled-beam system was selected due to the anticipated higher plug loads. Benefits included reduced duct work, higher ceiling heights, enhanced acoustics due to HVAC, improved thermal comfort and user experience, and delivery of 100% outside air to the spaces with no return-air component.

Figures 2 and 3 show the predicted modeled savings from a dedicated outdoor air system (DOAS) plus chilled-beam system type as compared with a LEED baseline. The chilled-beam system was chosen due to high plug loads in the space, resulting from a higher occupant density of roughly 80 sq ft/person thus 6 W/sq ft of plug loads. The central plant leveraged the climate, building form, and internal plug loads by providing a heat-recovery central water-source heat pump. This was used for first-stage cooling, and heat rejection is used for simultaneous heating at the exterior. The building envelope was optimized to ensure cooling loads could be met by active chilled beams with minimum outside air capacity. Exterior shading was designed to reduce solar / cooling loads. Ceilings were much higher than would have been possible with a conventional VAV system type.

High-performing systems and thermal comfort

Having thermal comfort discussions with the client can inform the architectural and mechanical teams of the potential to downsize or right-size systems both at the zone level and plant level. This can open up the discussion to using alternate high-performing system types that can be more efficient and provide added benefit with regards to thermal comfort and indoor air quality and user experience. This can also open up the dialogue between architects and mechanical engineers to optimize the building envelope to reduce peak loads.

Thermal comfort expectations and the use of operable windows with natural cooling, and how these systems can be tied to the HVAC controls, should be discussed with the owner for better understanding of operations. It is important to identify the use of operable windows as being separate from the minimum ventilation that is provided mechanically. The owner will often say no to operable windows if assuming the windows would be their only access to outside air.

Discussion of the impact of set thermal comfort criteria on user comfort and experience, as well as the potential decrease in first costs by under- or rightsizing equipment, can lead to allowances for upgrades to more efficient systems. It’s valuable to discuss the added benefits of more efficient systems to reduce annual energy, utility, and maintenance costs:

- Identify cost impacts and possible upgrades or the potential to use high-performance HVAC systems to meet energy-reduction goals set by the owner.

- Identify a system change or upgrade’s impact on indoor air quality and the resulting impact on the productivity of occupants.

- Identify impacts on high-performance building standards like LEED or the WELL Building standard, net zero certification, due to resulting low predicted energy use intensity, high efficiency, improved thermal comfort, individual thermal comfort control, etc.

Incorporating set thermal comfort criteria and integrating a high-performing envelope, potentially with operable windows, can enhance user comfort and experience. This strategy can potentially decrease initial costs by reducing the need to overdesign, reduce annual energy and utility costs, and further the potential to use high-performance HVAC systems to meet energy-reduction goals and reduce global warming.

Amarpreet Sethi is a senior associate at DLR Group’s Seattle office. Her expertise is in building optimization and energy services. She was also a Consulting-Specifying Engineer 40 Under 40 winner in 2014.