Dedicated outdoor air systems (DOAS) deliver dehumidified air to buildings to improve the indoor air quality and thermal comfort.

Learning objectives:

- Explain basic air system design techniques.

- List codes and standards relevant to dedicated outdoor air systems (DOAS).

- Apply these design techniques, with examples from two health care buildings.

There continues to be an increased demand for highly efficient HVAC system design and high-performance buildings that provide indoor air quality (IAQ) and thermal comfort that exceeds minimum code requirements and occupant expectations. Many jurisdictions are adopting the most recent ventilation standards and commissioning requirements to help achieve these design goals.

Air-handling units (AHUs) that provide pretreatment of outdoor air (OA; also referred to in some localities as pretreat units) have been standard in HVAC design for a long time. The unit takes in 100% OA and then filters, heats, cools, dehumidifies (or humidifies) the air, and introduces it into a mechanical room plenum where it is mixed with return air. With further filtration and treatment, the air is introduced into the space. It continues to be a good way to reduce the work of dehumidification of the air (moisture removal) a building air unit would need to perform and to achieve more effective energy use.

This approach also provides a positive introduction of required ventilation air, which results in positive building pressurization. This design approach is especially useful in humid coastal climates. One of the primary reasons for the air pretreatment is to decouple the latent and sensible cooling loads of the OA from the space’s cooling loads. This pretreated air is also an excellent method to supplement other devices such as active and passive-radiant and convective cooling technologies.

Ventilation standards such as ASHRAE Standard 62.1: Ventilation for Acceptable Indoor Air Quality have been in use since 1973 (originally as Standard 62) and are now updated regularly using ASHRAE’s continuous maintenance process. The introduction of pretreated OA and minimum ventilation requirements go hand in hand. The pretreat unit nomenclature has been used for a long time, but is now more commonly known as the dedicated outdoor air system (DOAS). Some of the functions and methods of air introduction include:

- Direct introduction of treated OA to each occupied space (OA direct to space)

- Introduction of treated OA to air-handling unit inlet (OA to AHU inlet)

- Introduction of treated OA to mechanical room plenum (OA to mechanical room plenum)

- Using treated OA for active chilled beams and other equipment needing primary air (OA to equipment).

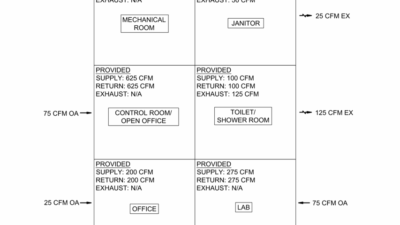

Each of these air-delivery approaches requires air balancing, air measurement, and controlled delivery of the air. The OA quantity is dependent in each case upon the required ventilation air for each space, meeting the exhaust air requirements and for proper building pressurization.

Calculating required ventilation air

ASHRAE 62.1-2010 allows for multiple ways to calculate and introduce the required ventilation air to the occupied zones. Two of the methods included in the ventilation-rate procedure are the 100% OA system and the multiple-zone recirculating system. The 100%-OA-system formula in paragraph 6.2.4 uses the ventilation required by each zone and sums all of the zones for the total air to be supplied by an air handler supplying only OA, which can be individually supplied as treated air to each zone or space.

The multiple-zone recirculating system uses one or more air handlers to supply a mixture of OA and recirculated air to more than one zone. The air formula noted in paragraph 6.2.5.1 calculates the primary OA fraction to be supplied based on the total ventilation air required divided by the total primary air required for proper treatment of the spaces. Further explanation and a ventilation system schematic are contained in Normative Appendix A of the standard.

OA direct to space

The first approach noted above (direct introduction of treated OA to each occupied space) requires a separate OA unit, separate supply duct system, air devices, and control strategy or sequence to maintain the correct air balance and air delivery. The air supply can be at space-neutral conditions or slightly cooler to assist in treatment of the space cooling requirements.

The goal with this approach is to provide the correct amount of ventilation air to the space that meets ASHRAE 62.1 requirements and/or satisfies the space-exhaust requirements. The supply air ductwork would be smaller than ducts for the total supply air volume; several similar room types could be combined and the air distributed through an air-terminal unit (ATU) to ensure the correct amount of air was being delivered at all times.

This approach is particularly suited to rooms that have individual recirculating units such as fan-coil units. Other spaces, such as conference rooms or libraries, that have fluctuating occupant loads and sometimes lengthy unoccupied periods may rely on occupancy sensors or demand-controlled ventilation (DCV) to meet the ventilation requirements for the space. DCV is defined by ASHRAE 62.1 as "any means by which the breathing-zone outdoor airflow can be varied to the occupied space or spaces based on the actual or estimated number of occupants and/or ventilation requirements of the occupied zone." An ATU could be controlled to modulate closed in the unoccupied mode, and the central OA unit would then be able to decrease its air volume in response to the reduced space needs either from measured airflow or static pressure control.

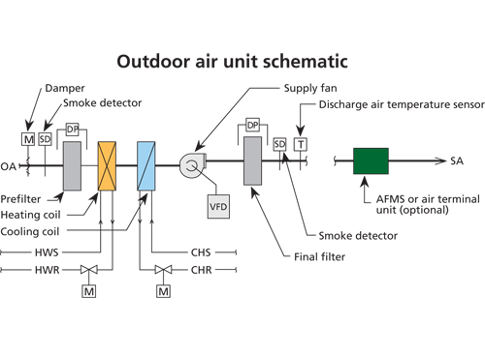

A typical DOAS-unit configuration is shown in Figure 1. A DOAS-unit schematic diagram showing some potential control components is shown in Figure 2.

Energy recovery

Dedicated OA units lend themselves to energy recovery from building exhaust air either as preheating or precooling of the outside air, depending upon climate zone, design conditions, and airflow rates. Table 6.5.6.1 in ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings identifies energy-recovery requirements based on climate zone, percent of OA at the Full-design flow rate, and the supply-fan-design airflow rate.

A schematic of an air handler with an energy-recovery device is shown in Figure 3. ASHRAE 90.1 requires energy recovery from exhaust air in paragraph 6.5.6.1 with some listed exceptions. This paragraph and exceptions should be carefully reviewed as needed for design compliance.

OA to AHU inlet

The OA-to-AHU configuration uses the DOAS unit to introduce air directly to the inlet section of an air handler serving the occupied spaces. This pretreated air would mix with the return air at the unit inlet, as it would normally be within 20 F of the return air temperature and would eliminate the need for an air blender and possibly the heating coil in the unit unless the unit also was designed for full-economizer operation to meet ASHRAE 90.1 criteria. The ventilation air would be balanced and controlled through an ATU or an airflow monitor station (AFMS). This method would indicate the correct amount of ventilation air is being provided to all spaces served by the unit, but not necessarily distributed to the most critical space at all times (see the multiple-zone recirculating system description above).

However, building pressurization could more easily be achieved. This distribution method works well with variable air volume (VAV) systems, is easily balanced, and with proper air-measuring controls can meet the energy requirements of ASHRAE 90.1 for single-zone VAV controls. For example, a rooftop or penthouse 100%-OA-unit could supply OA in a vertical riser to stacked mechanical room units below using measured airflow takeoffs to each AHU, possibly reducing the mechanical space needed in the building footprint.

OA to mechanical room plenum

Introduction of pretreated OA from a DOAS unit to the mechanical room plenum is similar to introducing it to the unit inlet, but allows for air mixing in the mechanical room prior to being drawn into the air handler that serves the occupied spaces. The ventilation air introduced into the room can be measured and monitored through an ATU or AFMS.

The calculation procedure would be the same as for the multiple-zone recirculating system. With the mechanical room under negative pressure, it is generally more difficult to measure the return air quantity, which may result in not being able to provide adequate building pressurization unless OA is also introduced directly into the building spaces. As the effectiveness of final filtration on the DOAS unit would be lost with this approach, a MERV 8 prefilter may be all that is required. A rooftop or penthouse 100% OA unit as noted in the preceding description could also be used for this application.

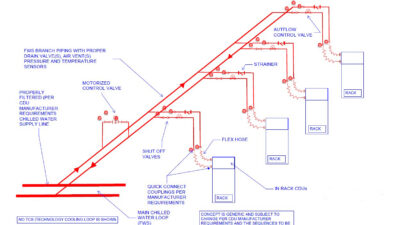

OA to equipment: chilled beams

Active chilled beams are defined by ASHRAE as a terminal device with an integrated, ducted air supply that induces ambient air through a hydronic coil for the purpose of transferring sensible heat to/from the space. Primary air supplied from a DOAS unit is discharged through nozzles in the room equipment at high velocity, which induces room air and is then mixed with the primary air. One part of primary air will generally induce 2 to 5 parts of ambient air, which then produces 3 to 6 parts of supply air. Design consideration for both primary air temperatures for space-relative humidity control and chilled-water temperatures to avoid condensation on the coil or the device is part of the needed design criteria. The quantity of primary OA being supplied to the chilled beam should be at least equal to the minimum required by ASHRAE 62.1 for ventilating the space type and occupancy.

Passive chilled beams are defined as those with the cooled element or cooling coil fixed in, above, or under a ceiling that cools mainly convectively using natural airflows. As no primary air is supplied to a passive beam, the space-ventilation requirements must be met by another means, such as direct supply to the space from the DOAS unit. These system types lend themselves to simplified and reduced mechanical room requirements, which also lead to controlled ventilation rates, overall energy reduction in fan horsepower, and possibly more uniform space temperature control.

Other HVAC health care and fan-powered terminal unit considerations

Health care design criteria with their specific room types, based on the procedure performed and occupancy, also have minimum requirements for air changes per hour (ACH) of OA. These minimum requirements are noted in the ventilation Table 7.1 in ANSI/ASHRAE/ASHE Standard 170-2013: Ventilation of Health Care Facilities. This standard is contained in the 2014 edition of the Facility Guidelines Institute’s Guidelines for Hospitals and Outpatient Facilities. A DOAS unit can provide the minimum ACH either directly to the space or through a central-station air handler. It is interesting to note that Standard 170-2013 currently does not address ventilation based on different occupancy densities or demand-controlled ventilation according to interpretation IC 170-2013-5. These criteria are left to ASHRAE Standard 62.1-2013.

Proper air filtration, as noted in Standard 170, also is required as these dedicated OA units are considered central station air handlers, especially if the unit delivers air directly to the space. It is also interesting to note that, according to interpretation IC 170-2013-3 of the standard, the purpose of Standard 170 is stated to "define ventilation system design requirements that provide environmental control for comfort, asepsis, and odor in health care facilities." As there is no mention of "acceptable indoor air quality," the official interpretation confirmed the exclusion of this term as it relates to the scope of the standard. Again, any requirement for acceptable indoor air quality is left to ASHRAE 62.1-2013.

Using a DOAS to supply primary air to fan-powered terminal units is also a method to provide positive airflow and meet minimum ventilation requirements of ASHRAE 62.1. This type of VAV system uses the constant primary airflow for ventilation and humidity control while the fan’s electronically commutated motor (ECM) varies the additional airflow requirements drawn from the plenum to meet space heating and cooling loads. Sensible cooling and heating coils can be part of the fan-powered ATU to meet these loads as well.

Benefits of a DOAS

There are many benefits to using a dedicated OA system in HVAC design. Some of these include:

- Space humidity control by removing the moisture to a level that will meet the space design criteria when blended with the ambient air

- Positive measurable ventilation quantities that provide code-required air-change rates or other ventilation criteria without having to over-air any particular space

- Fan energy reductions by being able to vary the primary airflow (and pretreatment) for unoccupied spaces

- Providing a means for varying control strategies for both the DOAS and other central station air handlers serving occupied spaces for both occupied and unoccupied periods Providing a means for building pressurization while meeting exhaust requirements and ventilation rates

- Centralizing the OA delivery, which enhances the opportunity for energy recovery

- Creating an opportunity for economizer operation in the unit with varying supply air delivery temperatures to meet space needs without the need for additional air heating or cooling.

A DOAS can be used to a building owner’s advantage to create a means for providing properly treated OA where needed, required quantity of ventilation air for occupied spaces, energy savings through exhaust-air-stream energy recovery, and control of building pressurization. Additional benefits include prefiltering of OA, which, in turn, may prolong the life of the filters and coils in central air handlers served by the DOAS. As each building type and occupancy requires specific design consideration, a DOAS unit may help solve many of the ventilation and indoor air quality needs.

J. Patrick Banse has more than 35 yr of experience in the consulting engineering field and is part of Smith Seckman Reid’s technical guidance team involved with codes and standards updates and QA/QC programs.