Everyone is aware of the shock hazard that is present with electrical equipment, but how aware are you of the arc flash hazard that may be present?

There has been a lot of emphasis on electrical safety within both our company and the construction/operations industry during the last couple of years. All of this emphasis is attributed to NFPA Standard 70E that was significantly revised in 2012. NFPA 70E is not a law, but rather a standard methodology for compliance with OSHA regulations stating that every employer must protect its employees from electrical hazards. It is not THE standard, but is widely accepted throughout the construction, operations, and maintenance industries. It is important to realize that a standard must be black and white, but cannot always cover the gray areas that a worker encounters on a daily basis. Therefore, a thorough understanding of hazards as well as appropriate training is needed to keep every worker safe.

Let’s begin this discussion with a very simple explanation of electrical hazards that may be present while performing commissioning work. Everyone is aware of the shock hazard that is present with electrical equipment, but how aware are you of the arc flash hazard that may be present? While a shock hazard exists from coming into contact with live energized conductors, an arc flash hazard may be present by just being in the same room with electrical equipment, whether or not the conductors are exposed.

An arc flash is caused by an electrical arcing fault or short between two energized conductors or an energized conductor and neutral or ground. The first component of an arc flash, the available energy in the arcing fault (measured in kilo-amperes or kA), is determined by the available short-circuit current or bolted-fault current at the location of the fault. There are a number of factors that determine this value including the available utility short circuit at the building source, the voltage of the system, the size of transformers and their associated impedance (or resistance to current flow), and the length and size of conductors in the system up to the point of the fault.

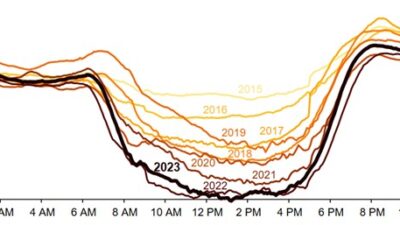

The second component of an arc flash is the duration of the arc. This is the most important factor in determining the intensity of an arc flash. A common misconception is that higher-voltage equipment or higher-amperage busways have a higher arc flash hazard. This may or may not be true. Often, the higher-voltage and -amperage systems produce arcing faults that have very high-arcing fault currents, but the upstream overcurrent-protection devices (OPDs) open and clear these faults very quickly. Therefore, the overall arc flash energy level (measured in calories/square centimeter) is relatively low for the energy that is available. Conversely, many points that are further along in an electrical distribution system, such as a motor control center or motor starter, can have relatively low available arc fault currents, but the OPD settings do not clear the fault quickly. This results in longer arc-fault duration and a much higher arc flash energy level. An example of these two scenarios is shown in Figure 1.

In Figure 1, an open-air 1,000-amp fault on a 40-amp primary service is illustrated downstream of a 12,460-amp (12.kV) fused switch. The Y axis of the chart represents time in seconds and the X axis represents fault current in amperes. The arc flash incident energy in this situation is only 0.25 cal/sq cm, which equates to a hazard risk category (HRC) of 0. The prohibited boundary (36 in.) to prevent a shock hazard is actually greater than the arc flash hazard boundary (6 in.).

Figure 2 shows both a bolted fault and the arc fault that could be generated in a motor control center for a chiller. As noted, the bolted short-circuit fault current is approximately 100,000 amps. If that fault were to occur, the upstream OPD would trip in approximately 0.05 sec. The maximum arc fault current is actually calculated based upon the minimum short-circuit current available, which is 40,000 amps. At this level, the OPD trip time is approximately 7 sec, resulting in an arc flash energy level of 299 cal/sq cm at a boundary of 505 in. This is a HRC of DANGEROUS—or, no arc flash PPE is available for protection of personnel—within a radius of 42 ft from the equipment.

Most people would say this hazard level is only applicable if the panel door is open with the live conductors exposed. This reasoning is incorrect. The equipment manufacturers test their equipment to withstand the short-circuit current rating and contain any products of combustion to prevent a fire. They do not rate their standard cabinets to withstand arc faults. Therefore, an arc fault incident could cause the enclosure to rupture and subject personnel to high arc flash energy levels in addition to flying shrapnel and other hazards. Only electrical equipment specifically rated for arc flash hazards can guarantee protection. Furthermore, while a greater chance of an arc flash exists when equipment is being switched, all electrical equipment can fail even under normal operation. Therefore, it is imperative that personnel are always aware of their surroundings and are diligent in mitigating hazards while performing their daily tasks. Work tasks should be performed away from energized equipment whenever possible, and proper precautions should be taken when working near energized equipment.

So what does this mean for test-and-balance and commissioning personnel? First and foremost, they must understand the hazards that may be present around electrically energized equipment. While a large motor control center is typically more dangerous, do not discount the 10-hp motor starter disconnect switch that is commonplace in many facilities. Personnel must search out the facts and understand the hazards. To do this, a person must be able to read an Arc flash warning label that should be posted on most new equipment. An example is shown in Figure 3.

This label provides all of the required information to determine what is needed to be safe around a piece of equipment. The flash protection boundary indicates the distance from the equipment where an arc flash could cause a second-degree burn to bare skin (1.2 cal/sq cm). Within this boundary, the stated HRC must be utilized to determine arc flash PPE as shown on the label. The shock hazard is also listed. The limited approach for unqualified personnel will typically be the same as the arc flash boundary. The restricted approach is determined by the voltage of the energized conductors. The minimum insulated-glove class will be provided on the label if work within the restricted approach boundary is required (i.e., voltage and current measurements). The prohibited approach should never be entered except when using test instruments or insulated tools along with the proper PPE (i.e., voltage-rated gloves).

If a detailed hazard label is not provided, there are other options. The electrical coordination and arc flash study can be obtained from the owner or engineer and referenced to determine the arc flash hazard and shock-hazard boundaries as well as the HRC or incident energy (cal. / sq. cm.) levels. Once these values are known, the information in Table 1, based upon data from Article 130 of NFPA 70E, can be used to determine the appropriate arc flash PPE for protection.

It is important to understand the purpose of arc-rated clothing. An arc flash incident can produce extremely bright light, intense heat, a large concussion or blast, vaporized particles, shrapnel, and poisonous gases. The arc-rated clothing is meant to protect the human body from sustaining life-threatening injuries. This does not mean that a person will not get burned or otherwise injured, but the clothing should sustain the arc flash energy without catching fire and causing more serious burns. Most serious workplace injuries from arc flash are not a result of the flash or blast itself, but are caused by secondary burning of a person’s clothing or burns to exposed skin. Therefore, flame-retardant clothing is the first line of defense in protection from an arc flash incident.

The data in Table 2, also derived from Article 130 of NFPA 70E, describes the voltage-rated insulted-glove classes for protection from shock hazards. All rubber-insulated gloves must be used with protective leather outer gloves and visually inspected before each use for holes, tears, or abrasions.

If the arc flash or shock-hazard levels cannot be determined, personnel should not perform energized work on equipment or be in close proximity to equipment that could exhibit an arc flash hazard. If possible, all equipment energy sources should be de-energized and locked out following appropriate lockout/tagout procedures, unless diagnostic testing is required or de-energizing the equipment poses a greater risk to employees or building operations (e.g., health care facilities).

In conclusion, proper safety procedures must always be followed even when personnel are not working directly on a piece of equipment. Always be aware of surroundings and identify hazards. If there are any questions about the safety of a situation, stop immediately, leave the area, and consult someone with experience to determine the proper course of action to perform work tasks. No task is worth the risk of death or injury.

Justin Garner is Houston brand manager at Engineered Air Balance Co. Inc. This article originally appeared in Associated Air Balance Council’s (AABC) TAB Journal. AABC is a CFE Media content partner. Edited by Joy Chang, digital project manager, Consulting-Specifying Engineer, [email protected]