Energy management is at the forefront for new Schneider Electric technology

PlantStruxure Process Expert System (PES) from Schneider Electric treats energy as a consumable, not a cost.

Rollout of Schneider Electric’s PlantStruxure Process Expert System (PES) at the ARC Advisory Group World Forum in Orlando offered attendees to discuss the larger issue of the evolving view of energy as a raw material.

“We’re seeing more active energy management,” said John Cavalenes, Schneider Electric’s product management and pre-sales manager. “Energy is a consumable now.”

The core of allows manufacturers and other industrial energy consumers to combines automation needs within a distributed control system (DCS) structure. The key combining a DCS and programmable automation system (PAC) is the greater awareness of energy management tools within the PES system.

It’s an issue Schneider Electric addresses as a supplier and a manufacturer. “We’ve reduced our own energy costs by about 30%,” said Andrew Roxburgh, vice-president of systems and service for Schneider Electric’s industry business. “We practiced on ourselves. Now we’re prepared to take that message out to the industry.”

Energy management, controls

“PlantStruxure PES is a leading edge offer in the field of process automation systems that brings the best from the PLC/SCADA and DCS worlds and combines this with integrated energy management features to deliver superior value throughout the lifecycle of a plant,” said Mary Ramsey, senior vice president of industry business, in the press release announcing the PES system. “The tight integration of the system ensures efficiency from design engineering through operation, and engineers can develop the configuration faster and more accurately, and maintenance teams can diagnose and solve problems faster to reduce the downtime of a facility,” she said.

The overall goal is to provide plant managers and other system operators with a dashboard that clearly shows energy spend across all of its forms, including electrical, natural gas, compressed air and steam. “It’s very flexible, and simple to maintain,” Roxburgh said. “The plant manager now gets a holistic view. It brings more visibility to the process.”

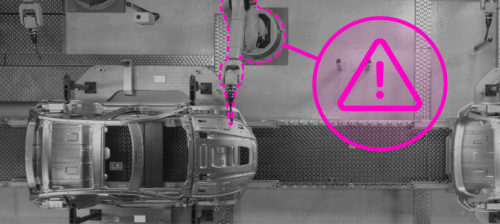

The advantage of the DCS portion of the PES system is to allow energy use to be treated as an out-of-range notification. That will allow greater awareness of how and where energy is consumed in any part of the manufacturing process, and also create greater visibility.

“PlantStruxure PES has the ability to provide clear process information that is crucial to driving production efficiency, including trend data, advanced alarm and events capabilities, and historical knowledge of performance,” Schneider Electric officials said in the press release. “PlantStruxure PES is also unique in its scalability and integration with a range of PAC systems, from basic PACs to more complex ones, depending on the needs of a machine or process.”

Streamlined convergence

The company also quoted Craig Resnick, vice president of consulting for ARC Advisory Group. “Technology advances continually provide opportunities for industrial facilities to improve energy efficiency, lower operating costs and increase process performance by integrating systems that streamline process automation and control," Resnick said. “Schneider Electric’s new platform, PlantStruxure PES, addresses this market demand by integrating multi-disciplined PAC applications while simultaneously incorporating the flexibility of a DCS interface. This capability allows production facilities to integrate automation, SCADA, and energy management into a common platform, reflecting the trend of solutions convergence in the marketplace.”

ARC World Forum is Feb. 11-14, in Orlando, Fla. www.arcweb.com

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.